Rotating Disc Contactor, Liquid Extraction Systems Manufacturer, Exporter

Sieve Plate Extraction Columns, Pulse Columns Manufacturer, Exporter

THE CONCEPT

A Rotary Disc Contactor (RDC) is a type of process column used in the Chemical Process Industry for Liquid- Liquid Extraction, remove impurities from Liquids. It is used widely in the Pilot Plant studies of critical Extraction of Liquid Phase.

THE DESIGN

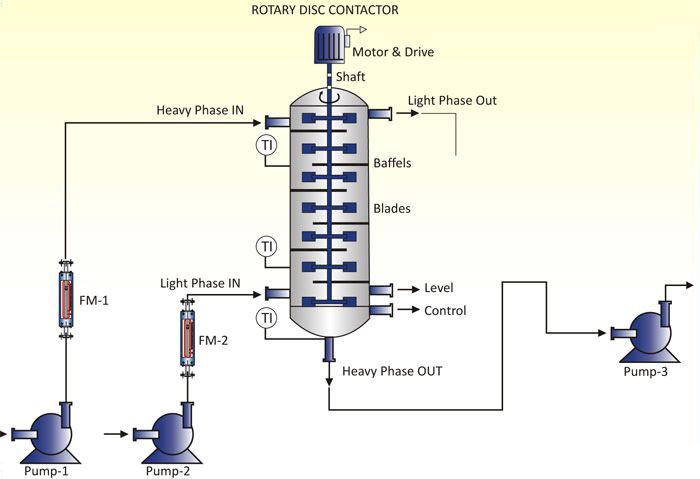

The System consists of a vertical cylindrical Column , divided lengthwise into a number of equally spaced compartments by series of stator rings. A rotor disc supported by a shaft is centred in each compartment. The solute is dispersed in droplets due to Agitator Disc. The Mass Transfer occurs between the Droplets and surrounding carrier liquid in continuous phase.

THE BACKGROUND

Liquid- Liquid Extraction: – Liquid- Liquid Extraction is an important unit operation for wide range of application in the Chemical Process Industry. Unlike Distillation, which based on Boiling Point differences, extraction is based on their relative solubilities in two immiscible liquids. Extraction is always preferred over Distillation, for separation application which are not possible with Distillation and its Cost- effectiveness.

In Liquid-Liquid Extraction a Liquid (Carrier) containing the components to be separated is passed in an Extraction Column where it contacts a solvent. The two liquids must be immiscible or slightly miscible. A dispersion is formed with one liquid in the form of droplets. The Mass Transfer takes place between the Droplets and solvent in continuous flow. Based on density differences, the two liquids are separated, and are recovered at the top or bottom of the Extraction column.

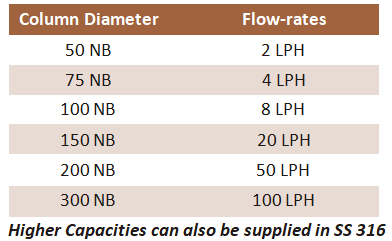

In Rotary Disc Contactor the separation is based on Counter Current principle, higher density liquid enters from top and lower density liquid enters at bottom. The two liquids pass each other as they move through the compartments, because of density difference. The process of mixing and separating two liquids is reinforced by rotation of the rotor disc. Varying the Column Diameter, Column Length, Compartment Height, Flow Speed and Rotational Speed allows for adjustment of Droplet Size in the Dispersed Phase.

The Features:

- Reduced Solvent Use

- Continuous Operation

- Complete Automation possible

- Supervision Free Operation

- Minimum Space Requirement

- Cost Effective

TYPES OF ROTARY DISC CONTRACTOR

Karr Column: The shaft is oscillated in vertical axis along-with the rotational movement i n h orizontal axis.

FEATURES:

- High Efficiency and Uniform mixing

- Best suited for Emulsions

Scheibel Column: The Shaft has Turbine Impellers and I nner & O uter B affles.

FEATURES:

- Internal Baffles provides High efficiency

- Best suited for requirement of higher no of contact points

Pulsed Column: A Pulsation is created by passing compressed air along-with Shaft Agitation

FEATURES:

- Limited Column Dimensions are required because of Pulse Energy

- Best Suited for Nuclear applications

- Suited for Corrosive material

Rota ry Disc Contactor with Late ra l Movement: The shaft moves laterally along-with r otational m ovement

FEATURES:

- High Efficiency

- High Dispersion

STANDERD PRODUCTS:

- High Pressure Stirred Autoclaves- 2 Ltrs to 25 Ltrs, 3- 350 BarG with SS-316/ Glass/ Hastelloy

- High Pressure Glass Autoclaves

- Rotary Evaporators- 2 Ltrs to 100 Ltrs capacity

- Heating and Chilling Bath with Circulators- -600 C to 2500 C for Reactors from 1 Ltr to 100 Ltrs

- Glass Distillation Units

- SS and Hastelloy Distillation Units

- Photochemical Reactors

- Accessories for Julabo/ Huber Heating & Cooling Circulators

- Diaphragm Vacuum Pumps and Digital Vacuum Controllers

- Skid Mounted Pilot Plant Systems

CUSTOMIZED SPECIALISED PRODUCTS:

- Pharma Lab Filters- Nutsche Filter

- Rotary Disc Concentrators- Liquid-Liquid Extraction systems

- Fixed Bed Reactors

- Chemical Vapour Deposition- CVD Reactor system

- Plug Flow Reactors

- Continuous Stirred Tank Reactors- CSTR

- Combined Flow Reactors

APPLICATIONS:

- Liquid- Liquid Extraction

- Separation of components with close boiling points

- Continuous Flow Reaction Chemistries

- Waste Water Treatment

- pH alterations

INDUSTRIES:

- Biotechnology

- Effluent Treatment

- Petrochemicals

- Food Industry

- Inorganic Chemicals

- Pharmaceuticals

- Polymer Process

- Petroleum

- Petrole Metal Industryum

- Nuclear Industry

SPECIFICATIONS

Standard Products:

- High Pressure Stirred Autoclaves- 2 Ltrs to 25 Ltrs, 3- 350 BarG with SS-316/ Glass/ Hastelloy

- High Pressure Glass Autoclaves

- Rotary Evaporators- 2 Ltrs to 100 Ltrs capacity

- Heating and Chilling Bath with Circulators- -600 C to 2500 C for Reactors from 1 Ltr to 100 Ltrs

- Glass Distillation Units

- SS and Hastelloy Distillation Units

- Photochemical Reactors

- Accessories for Julabo/ Huber Heating & Cooling Circulators

- Diaphragm Vacuum Pumps and Digital Vacuum Controllers

- Skid Mounted Pilot Plant Systems

Customized Specialised Products:

- Pharma Lab Filters- Nutsche Filter

- Rotary Disc Concentrators- Liquid-Liquid Extraction systems

- Fixed Bed Reactors

- Chemical Vapour Deposition- CVD Reactor system

- Plug Flow Reactors

- Continuous Stirred Tank Reactors- CSTR

- Combined Flow Reactors