High Pressure Autoclaves, High Pressure Stirred Autoclaves Manufacturer, Exporter

High Pressure Stirred Lab Autoclaves, High Pressure Reactors Manufacturer, Exporter

High Pressure Autoclaves / Reactors / Pressure Vesssels

Types :

- Bottom Stirred Autoclaves

- High Pressure Autoclaves

- Autoclaves for Corrosion Testing

- Autoclaves for Study of Gas Hydrate Formulation

- Autoclaves for Calorimetery

- Low Pressure Glass & Interchangeable Glass-Metal Autoclaves

- Gas Induction Reactors

- Multiple Parallel Reactors

- High Throughput Catalyst Screening

- Non Stirred Pressure Vessels

- Acid Digestion Bombs / Hydrothermal Pressure Vessels

- Shaker Hydrogenator

- Supercritical Fluid Extraction System (SCFC)

- Continuous Flow Stirred Tank Reactor (CSTR)

- Pilot Plant & Customized Systems

- Low Pressure Reactors with Heating Cooling Circulators

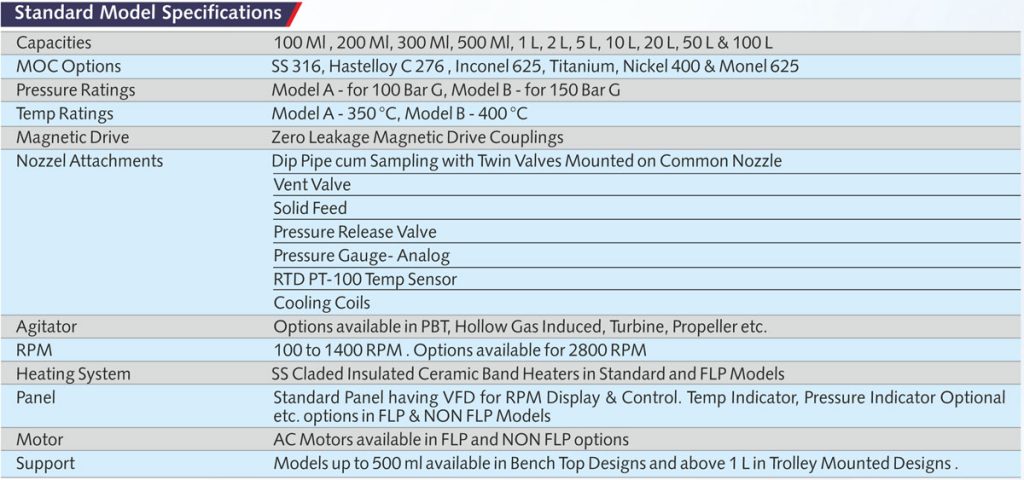

Features :

- 25 ml to 2000 ltr volume

- Stirred & Non-stirred Reactor / Pressure Vessels

- Maximum design pressure upto 700 bar & temp. upto 650°C

- Material: SS316 / SS316L, Monel, Nickel, Inconel Titanium, Hastelloy B/C, Tantalum Lined Zirconium etc.

- High torque maintenance free Zero Leakage Magnetic Drive Coupling

- All design as per ASME coded with CE-PED or U/U2 stamp marking optional

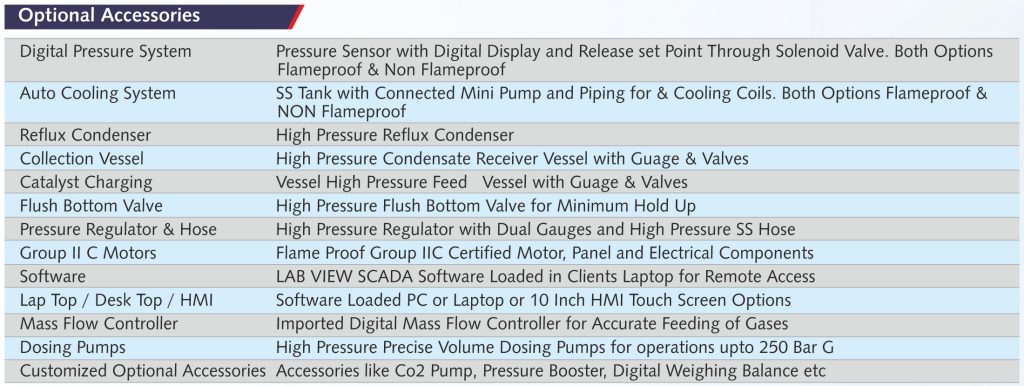

- Fully automated PC controlled High Pressure System / Pilot Plants, Pilot Plant to continuously monitor control & record various parameters with touch panels & recipe management

- Complete Pilot Plant with automatic temp., pressure, liquid & gas flow, motor torque / current, RPM, pH, conductivity, turbidity, dissolved oxygen, level, IR etc. controls, auto cooling system, chiller, condensor for Distillation Reflux, Thermic Fluid Heating / Cooling System etc.

- Complete flame / explosion proof / ATEX certified systems suitable for group IIA, IIC gases (optional)

- CE, UL, CSA certified electrical & controls (optional)

- ATEX certified electrical & controls (optional)

Applications :

-

It is used for high-pressure high-temp. chemical reactions like bomination, alkylation, caoboxylation, amination, catalystic reduction, esterification, dehydrogenation, chlorination, halogenation, ethoxylation, hydrogenaiton, nitration, methylation, ozonization, oxidation, polymerization, sulphonation etc.

•To produce chemicals in small quantity in batch or continuous mode

•For synthesis of hydrogenation, epoxydation, acetylation, grignard reaction, photochemical reaction, nitration, acylation. •To invent new molecules / chemicals & study reaction parameters.

•For high throughput catalyst screening.

•For quality control & process improvements - For static, dynamic, loop & electrochemical HPHT corrosion testing

- For Supercritical CO2 Solvent Extraction / reaction / drying / evaporation system

- Gas hydrate formation

- For reaction calorimetetry to study heat of reaction

- For hydrogen disbonding test

- For high pressure storage & transfer of gas / liquid / slurries

- Soaking of diamonds / precious stones

- For acid digestion

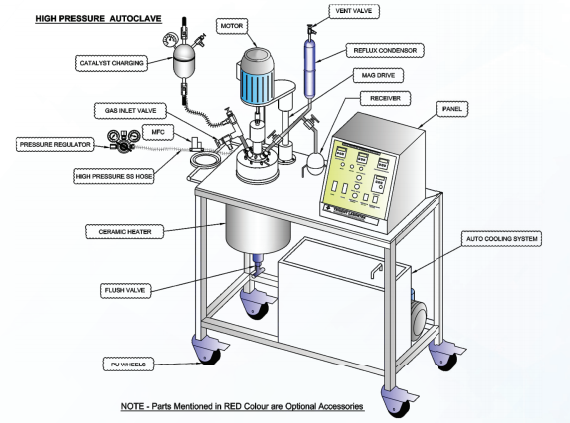

High Pressure Stirrer Autoclaves