Fixed Bed Reactor Manufacturer, Exporter

Tubular Reactors, Packed Bed Reactor Manufacturer, Exporter

Concept

Fixed Bed Catalytic Tubular Reactors are Widely used in Research & Development Activities for Catalyst Screening and Testing applications Under High Temperature and Pressure Conditions and also for Processes like Hydrogenation, Oxidation, Liquification etc.

These Multiphase Gas and Liquid Reactors are Used in Testing of Fine Chemicals, Petrochemicals, Refineries and Oil & Gas Industries.

Typical System

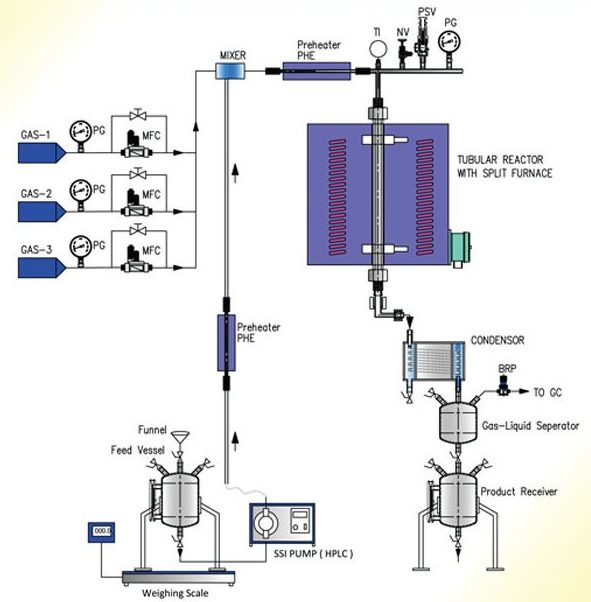

A standard Fixed Bed Reactor System consists

- Liquid Feed Vessel with High Pressure Dosing Pump

- Mass Flow Meters for Multiple Gas Feeds

- Static Mixer for Gases &Liquid Vapour

- High Temp Electric Furnace for Reactor

- Back PressureValve

- Control Panel for Flow & Temp Control

- Preheater -Vapourizer Feed for Liquid

- Preheater for Feed Gases

- Main High Pressure Tubular Reactor

- Gas Liquid Seperator

- Product Receiver

- Aluminum Profile Skid for Entire Unit

Units are available in Compact Skid Mounted Designs as per our standard Packages or as per clients Designs Optional Advanced Models with Wet Gas Meter, SCADA and data Recording, PLC and Computer system are also available as per Clients Requirements

Salient Features

- Units available for Operating Pressures upto 150 Bar Gand Temperatures up to 1100 Deg C

- Reactor Capacities from 5 cc to 200 Ml available

- Reactors available in Various MOC like SS 316 L/SS310R/ Hasteloy C276, Inconel 800 etc

- Compact Skid Mounted user Friendly Units