CONTINUOUS STIRRED TANK REACTOR (CSTR)

A Continuous Stirred Tank Reactor (CSTR) is a type of chemical reactor where reactants are continuously fed into a vessel, mixed by an agitator, and products are continuously removed, operating at steady state. CSTR’s are widely used in industrial processes for producing chemicals, pharmaceuticals, and other products, particularly when continuous flow and well-mixed conditions are essential.

KEY FEATURES & CHARACTERISTICS:

Continuous Flow:

Reactants enter and products leave the reactor continuously, ensuring a steady-state operation.

Perfect Mixing:

The agitator ensures that the reactants are uniformly mixed throughout the vessel, creating a homogeneous reaction environment.

Steady State:

The reactor operates under constant conditions, with the product outlet stream having the same composition as within the tank.

Back mixing:

CSTR’s are characterized by back mixing, meaning the effluent stream has the same composition as the contents of the reactor, unlike a plug flow reactor.

Versatile:

CSTR’s can be used for various reactions, including Liquid-Liquid, Solid-Liquid, & Gas-Liquid Reactions.

Scalable:

CSTR’s are relatively easy to scale up from laboratory to industrial applications.

ADVANTAGES OF CSTR’S:

Efficient Mixing:

The constant agitation ensures a uniform reaction rate and minimizes any temperature or concentration gradients.

Continuous Operation:

CSTR’s enable continuous production, reducing the need for batch processing and associated downtime.

Temperature Control:

The well-mixed nature of CSTR’s facilitates precise temperature control, crucial for many reactions.

Solid Handling:

CSTR’s can handle solid-liquid mixtures and are suitable for processes involving solid catalysts or precipitates.

Reliability and Safety:

The continuous and well-controlled nature of CSTR’s can improve operational reliability and safety.

APPLICATIONS:

CSTR’s find applications in various industries, including:

- Chemical Synthesis: Producing chemicals, polymers, and other chemical products.

- Pharmaceuticals: Manufacturing pharmaceutical products and intermediates.

- Biological Processes: Fermentation, cell culture, and other biological processes.

- Wastewater Treatment: Treating wastewater and removing pollutants.

- Polymerization: Producing polymers through various polymerization methods.

- Catalytic Hydrogenation: Performing catalytic hydrogenation reactions.

Design and Operation:

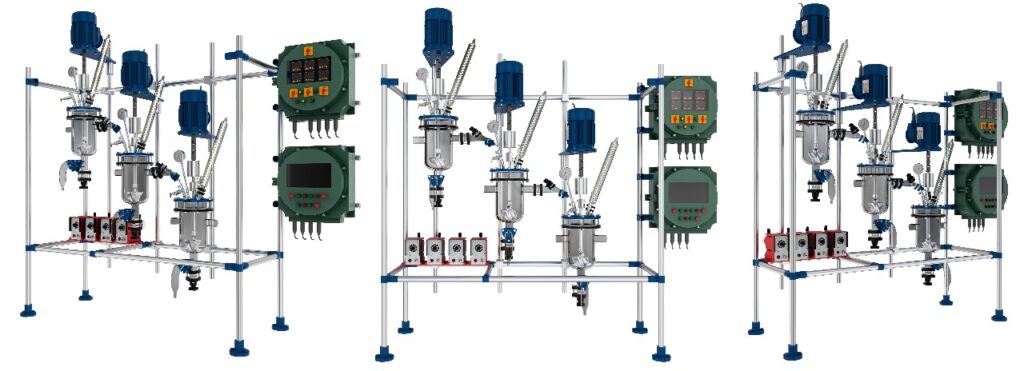

Reactor Vessel

Typically, a Cylindrical Tank made of Borosilicate Glass, SS 316, Hastelloy C-276, Hastelloy C-22, Inconel 625, Titanium G-2.

Agitator/Stirrer

A Mechanical Device that ensures Continuous and Uniform Mixing of the reactants.

Inlet and Outlet Ports:

Ports for introducing reactants and removing products.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.